Click on the picture to see full-size format.

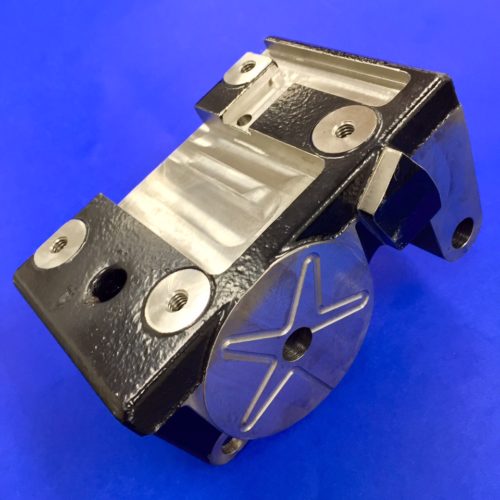

CNC Machining

CNC MILLING

Quest Specialty Products has significant and broad capability with CNC Milling. This includes a spectrum of part geometries that are from basic straight 3-Axis parts to complex parts requiring multi-axis fixtures.

We have numerous 40 and 50 taper machining centers, some with high volume pallet changing capability. We have high-speed spindles as well as part probing capability, 4th axis machining, and high-pressure through-spindle coolant. Quest has machines with various work envelopes to 50 inches. We can work with many different materials from plastics and composites to aluminum and copper alloys…

We can work with basically all steel alloys…. That includes stainless alloys and high-grade aerospace alloys like 15-5, 13-8MO, 17-4, 300M, 440C, I718 and many more.

Look to us to tackle any of your CNC milling requirements and challenges.

Here are some examples of some of our Aerospace parts. Click on the picture to enlarge.

Here is a parade of parts in slide format. Click to play.

Here are some examples of some of our Automotive aftermarket parts. Click on the picture to enlarge.

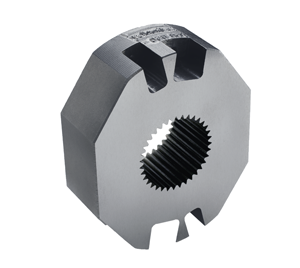

CNC TURNING

Quest Specialty Products has one of the largest CNC turning capacities in the region. We have through- spindle bar capacity up to 4-inch diameter bar. We have many different CNC Turning center configurations from basic 2-axis machines to several live-tooled 6-axis machines and everything in between. We can produce and automate many different multi-axis part configurations utilizing and combining C-axis contouring with axial and right angle milling. We can run material types in our CNC turning centers from plastics to any number of alloys in steel, aluminum, copper, stainless as well as exotics. Turn to Quest for you CNC turning requirements!

Click on the picture to see full-size format.

Click on the picture to see full-size format.

CNC GRINDING

Quest Specialty Products augments our CNC Turning capability with CNC Grinding. We can do both OD work and ID work in terms of CNC Grinding and can go to 40” between centers with respect to part length. We routinely hold production tolerances down to +/-.0001 inches. Our climate controlled facility helps us remain consistent in holding these extremely tight tolerances.

To see examples of CNC Grinding click the picture below.

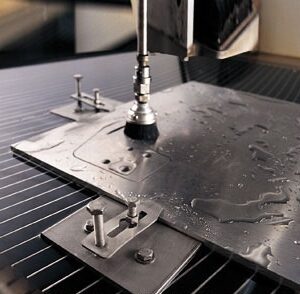

CNC WATER JET

Quest Specialty Products has CNC Water Jet capability that complements our comprehensive manufacturing resources. Our CNC Water Jet allows us to efficiently and accurately cut intricate shapes with widely varied thicknesses in any number of materials. The waterjet has no heat affected zone and as such there is no part warpage, distortion or material hardness gradients post-cut. We welcome any quote opportunities to use our Waterjet and its software to efficiently and cost effectively produce the parts you need.

Click on the picture to see full-size format.

Click on the picture to see full-size format.

CNC WIRE EDM

Quest Specialty Products has Wire EDM capability for very accurate, tight-tolerance part production. This capability is often used with our CNC milling and turning work. We have a wire EDM work envelope up to 18”x20”x10” and have fixtures that can allow us to cut intricate detailed features in any material that is EDM compatible.

If you have a part that requires Wire EDM we have all the necessary resources to provide you a turn-key solution.